Mold Development

SKS uses the latest CAD/CAM software to take drawings in any format and design a tool that is able to hold tight tolerances with practically no machining. SKS works closely with tool makers to reduce the lead time and lessen the expense of the customer.

SKS engineering design experts will support all your needs. including:

- Die casting aluminum or zinc metal selection

- Design improvements

- Die casting prototypes

- Mold flow analysis

- Die casting molds

- Die casting tolerances

- Machining and fixtures

- Surface finishing and assembly

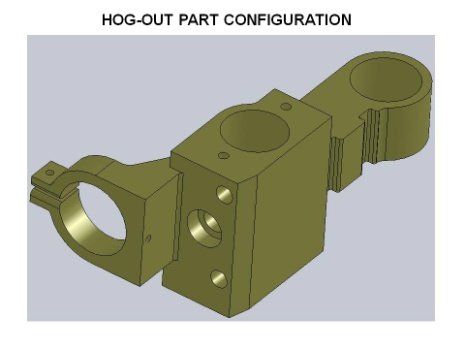

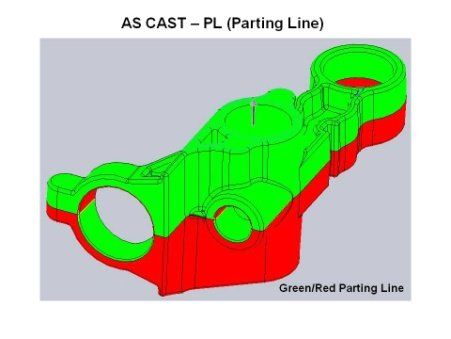

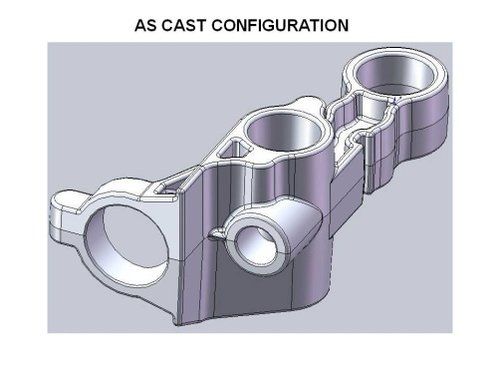

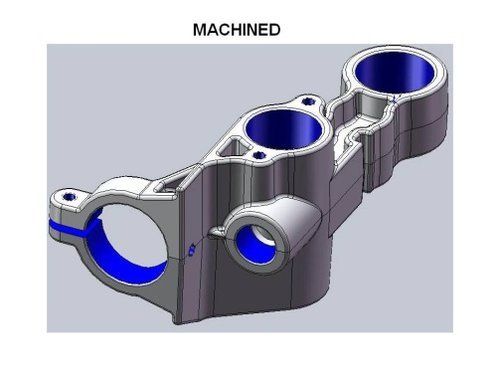

Most die cast parts are specified as replacements for machined parts or other casting methods, typically achieving significant cost savings through faster production and/or eliminating secondary operations such as milling, drilling, and mechanical fastening. Machining process of die-cast parts must be considered well before any order for the tooling is released. A careful evaluation of machined requirements can lead to redesign for net shape die-casting or near-net shape with reduced number of operations.

Die Casting

The basic die casting process consists of injecting molten metal under high pressure into a steel mold called a die. Die casting machines are typically rated in clamping tons equal to the amount of pressure they can exert on the die. A complete die casting cycle can vary from less than few seconds for small components weighing less than an ounce to two-to-three minutes for a casting of several pounds, making die casting the fastest technique available for producing precise non-ferrous metal parts.

Die casting can be produced in nearly every conceivable size and shape – from the smallest electronic component requiring precise engineering and weighing less than one gram, to the largest automotive part requiring durability and strength. Die casting provides the freedom to design intricate configurations because knowledge about the die casting process ensures that the components will maintain their integrity through disassembly, repair, re-manufacture, and re-assembly. The die casting process results in castings with extremely close tolerances and reduced draft angles, often eliminating the need for finish machining operations.

Aluminum

Aluminum alloys have proved ideal for a wide range of products because of the unique combination of qualities they possess: light weight, good corrosion resistance, high tensile strength, high dimensional stability, high thermal and electrical conductivity. Alloy 380.0 aluminum die casting alloy, has been found meet customers’ various needs. Importantly, SKS can also cast aluminum alloys 360, 390, and 413.

Zinc

Die casting with zinc-base alloys is one of the most efficient and versatile production methods to manufacture accurate, complex, and detailed metal components. In general, the mechanical properties of zinc alloy die castings at normal temperatures are superior to sand castings of grey iron, brass, and aluminum, particularly in toughness and impact strength. They are much stronger, tougher, and more dimensionally stable than injection molded plastics. Many components normally manufactured in iron, copper, aluminum alloys, or plastics can be produced as zinc alloy die castings. These show improved properties, often at reduced cost.

SKS can cast Zamak #3, #5, #7, ZA8, ZA12, and ZA27. Zamak is characterized by excellent retention of impact strength and long-term dimensional stability. It has been used for decades in a multitude of engineering applications and the properties and performance are excellent.

Machining

90% of our customers’ castings require secondary machining through our CNC centers. Dedicated machine centers are ideal for high volume production as well as short runs along with test pieces and or prototypes.

The combination of equipment (manual and CNC machining) allows SKS to develop and implement the most cost effective solution for your parts.

Finishes

- E-Coating

- Anodize

- Alodine

- Non-Chrome Passivate

- Powder Coating

- Electroless Nickel Plating